CASE STUDIES

Problems Solved

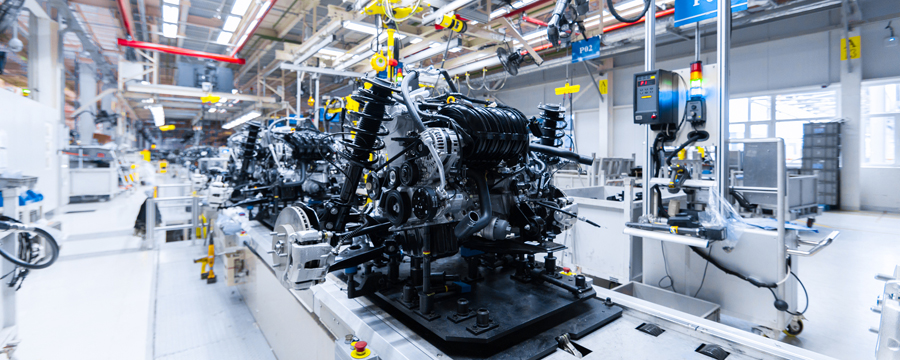

The head of a manufacturing plant contacted JAG when a glitch in their assembly line was damaging materials. JAG owner Javier Garcia came to the plant, studied the problem and came up with a way to fix it by fabricating and installing an attachment to protect materials on the line. His solution eliminated the problem, reducing waste and restoring efficiency to the plant.

Investments Protected

An local food processing plant handled very expensive equipment, which they would transport on mass-produced carts. Inevitably the carts would topple over or lose a wheel and the pricey equipment would get damaged. Javier built an extremely stable custom cart that cradled the sensitive hardware and latched it in place, preventing future accidents and saving the company thousands of dollars.

Safety Enhanced

On one job, the JAG team noticed that employees in a food-processing facility were handling a sharp blade used to cut frozen meat. Although they were there on another project, JAG owner Javier Garcia saw the potential danger and came up with an idea: he went back to his facility and designed and built a custom protective cover that locked the blade in place and made it easy and safe to transport.

Facilities Improved

A manufacturing facility wanted to create a stylish, themed outdoor break area for employees. They hired JAG to build the space with a retro industrial look, with steel columns, aluminum siding, stamped concrete and a tin roof. The JAG team provided a complete turnkey remodel, creating a fun, inspiring place for employees to recharge.

Vision Executed

A striking visual space makes a big impression on your customers, employees and other stakeholders. JAG Professional Services can enhance your site with design elements that reinforce your brand and reflect your company culture, from distinctive interior and exterior signage to a dramatic, backlit restaurant bar.